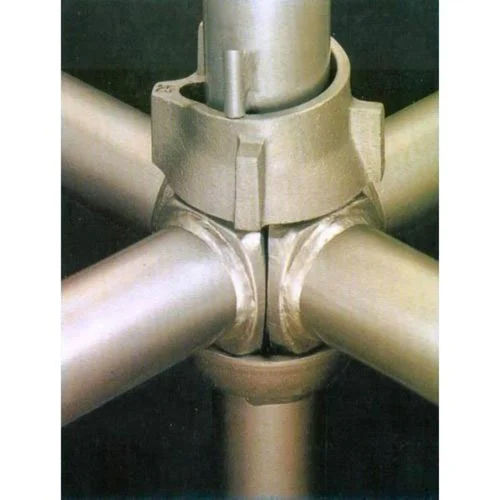

Mild Steel Cuplock Scaffolding System

70 आईएनआर/Kilograms

उत्पाद विवरण:

- गठित करना

- प्रॉप हेड

- विशेषताएँ High Strength, Corrosion Resistant, Quick Assembly

- रंग Silver/Galvanized

- आस्तीन का आकार 150 mm

- वज़न 17-20 kg/meter (depends on specification)

- तकनीक अन्य

- Click to view more

X

माइल्ड स्टील कपलॉक स्कैफोल्डिंग सिस्टम मूल्य और मात्रा

- किलोग्राम/किलोग्राम

- किलोग्राम/किलोग्राम

- 50

- Top & Bottom Cups

- 100+

- Up to 30 meters

- 48.3 mm

- 10+ Years

- 500 mm

- 48.3 mm

- ±0.5 mm

- EN 12810/12811

- MIG/ARC welding

- 3.2 mm

- -20°C to 70°C

- IS 1161/1239 Standard

- Yes

- Bundled or as per requirement

- 3.0 mm

माइल्ड स्टील कपलॉक स्कैफोल्डिंग सिस्टम उत्पाद की विशेषताएं

- हॉट डिप गॅल्वनाइज्ड

- High Strength, Corrosion Resistant, Quick Assembly

- Up to 3000 mm

- 2.0 kN/m²

- कंस्ट्रक्शन

- Silver/Galvanized

- 150 mm

- 17-20 kg/meter (depends on specification)

- अन्य

- 48.3 mm

- स्टील

- 1000 mm, 1500 mm, 2000 mm, 2500 mm

- कपलॉक

- Customizable

- 1200 mm

- 3.2 mm

- Top & Bottom Cups

- 100+

- Up to 30 meters

- 48.3 mm

- 10+ Years

- 500 mm

- 48.3 mm

- ±0.5 mm

- EN 12810/12811

- MIG/ARC welding

- 3.2 mm

- -20°C to 70°C

- IS 1161/1239 Standard

- Yes

- Bundled or as per requirement

- 3.0 mm

माइल्ड स्टील कपलॉक स्कैफोल्डिंग सिस्टम व्यापार सूचना

- 5000 प्रति महीने

- 2-10 दिन

उत्पाद विवरण

High-strength mild steel is used to create the sturdy, adaptable Mild Steel Cuplock Scaffolding System. Its essential parts, which cooperate to offer stability and security, are clamps, cups, horizontal ledgers, and vertical standards. It makes use of cutting-edge production techniques including welding and galvanisation and is made to be quickly assembled. Tools for cutting, bending, and welding are examples of essential machinery. It provides support for large loads and intricate structures and is widely employed in the engineering, industrial, and construction sectors. Because of the systems versatility, it may be set up in a variety of ways. Components usually have diameters between 48 and 60 mm, which guarantees strength and longevity under harsh conditions.

Reliable Construction and Safety

Designed to prioritize workplace safety in construction, the Cuplock system utilizes MIG/ARC welding for all joints and provides a stable working platform up to 30 meters high. The lockable Top & Bottom cups firmly secure the tubes, minimizing accidental dislodgement. With fire resistance and robust surface treatment, it maintains integrity under harsh site conditions.

Superior Durability and Corrosion Resistance

Made from hot-dip galvanized mild steel, the components offer extended durability and resistance to corrosion, enabling more than 100 reuse cycles and exceeding a ten-year lifespan. Whether stored at -20C or 70C, the system remains structurally sound, sustaining performance through years of use in varied environments.

Efficient Assembly and Customization

With standardized tube sizes48.3 mm diameter and customizable lengths ranging from 1000 mm to 2500 mmthe system offers versatility and quick assembly. Each part, from the adjustable prop heads to sleeve sizes of 150 mm, can be tailored to project requirements. Packing is flexible, arriving bundled or as specified to facilitate seamless logistics.

FAQs of Mild Steel Cuplock Scaffolding System:

Q: How is the Mild Steel Cuplock Scaffolding System assembled on-site?

A: The system is assembled using standardized mild steel tubes and components that interconnect via Top & Bottom Cups. These cups securely lock ledgers and standards in place, enabling quick and safe assembly without requiring complex tools. MIG/ARC welded joints add to the speed and reliability during erection.Q: What safety standards does the cuplock scaffolding system comply with?

A: This scaffolding system meets IS 1161/1239 and EN 12810/12811 standards, ensuring strict adherence to safety, durability, and fire resistance requirements commonly demanded in construction projects across India.Q: When should the cuplock scaffolding system be used on construction sites?

A: Cuplock scaffolding is suitable for use whenever structural stability, height accessibility, and quick deployment are required. It is designed for platforms up to 30 meters high, making it ideal for industrial, commercial, and residential construction activities.Q: Where can the cuplock scaffolding system be installed?

A: This system is adaptable to various environments, including outdoor construction sites, industrial zones, and maintenance projects. Its fire-resistant, corrosion-resistant properties and broad temperature tolerances (-20C to 70C) allow installation across diverse Indian climates.Q: What makes the Mild Steel Cuplock Scaffolding System beneficial for large projects?

A: Its robust hot-dip galvanized steel tubes, customizable sizes, and efficient locking mechanism provide high strength and safety. Supported by more than 100 reuse cycles and a service life of over ten years, it ensures cost-effectiveness and reliability for extensive, long-term construction projects.Q: How does the system ensure fast and secure erection with minimal labor?

A: The cup-locking mechanism and modular design allow rapid connection of ledgers and standards, reducing installation time and labor needs. Each component fits precisely, with tolerances of 0.5 mm, promoting a seamless setup and dismantling process.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email